The Vacuum Infusion Process

CCG specializes in vacuum infusion, the most cost-effective method for molding large structural parts, including bridges, rail platforms, camels for sea vessels or large pipe pilings.

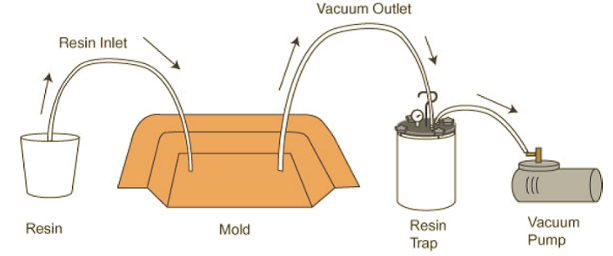

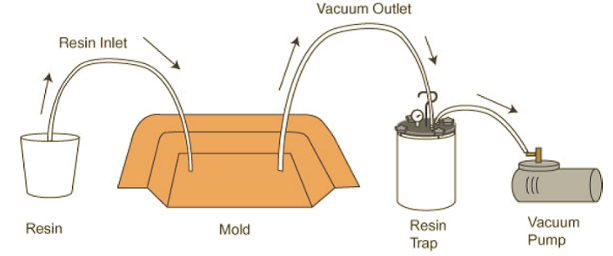

During the process, dry fiber materials are placed into a shaped mold and covered with a sealing plastic. Once the reinforcement materials are under complete vacuum conditions, precisely positioned tubes introduce liquid polymer resin into the mold. The vacuum comes into play to drive resin throughout the fiberglass reinforcements. Though more time-consuming than other methods, vacuum infusion is a more customizable process that creates a maximum fiber-to-resin ratio for high-strength FRP parts and shapes.

There are 6 steps to the vacuum infusion process:

1. Lay down fiberglass - First, technicians lay down dry fiberglass fabrics, similar to textiles. These fabrics are layered and oriented according to specific design requirements.

2. Position internal core - The internal core is placed on the bottom facesheet. Vertical fiberglass in the core will become the shear webs. Closed cell foam offers shape until the part is completely molded. The desired amount of fiberglass can be placed on the foam to increase the structural properties of the webs.

3. Seal bag - To achieve a vacuum and infuse polymer resin into the part, a bagging sheet is sealed to the molding tool.

4. Infuse resin - Atmospheric pressure pushes the liquid resin throughout the large part and wetting out all the fibers.

5. Cure and remove - Once the resin is infused, a chemical reaction creates heat, curing the resin into a solid part. The part is then removed.

6. Apply finishes - To complete the part, a number of finishing operations are performed, such as sanding, drilling, applying the nonslip overlay, adding drainage scuppers, and applying coatings for extra protection or added aesthetics.

Benefits of the Vacuum Infusion Process

With the vacuum infusion process, resulting products are both stronger and lighter thanks to the improved fiber-to-resin ratio.

Other key benefits include:

- Consistent resin usage

- Less wasted resin

- Huge range of possible part sizes

- Unlimited setup time

- High consistency and repeatability

- Cleaner process than traditional FRP processing

- Minimized styrene emissions (due to resin curing in a closed environment)

- Minimal to no voids in the finished laminate

- Strong end product due to minimal voids

- Better working environment (especially compared to an open molding alternative)

- Ability to use standard composite tooling (as long as it holds a vacuum and the flange is wide enough to seal the bag)

Vacuum infusion is also highly controllable, as only three variables affect the resin flow: the permeability of the laminate, the pressure differential in the cavity in relation to atmospheric pressure; and the viscosity of the resin.

Compared to other closed mold techniques, vacuum infusion involves higher consumable costs and slower cycle times. But for large parts, the advantages are clear.