DAYTON, Ohio (April 10, 2019) Marine piling products come in all shapes and sizes from wood and plastic to steel and concrete, but the Department of Transportation (DOT) agencies tasked with replacing aging fenders are bypassing these options for eco-friendly, corrosion-resistant fibre reinforced polymer (FRP) pilings.

DAYTON, Ohio (April 10, 2019) Marine piling products come in all shapes and sizes from wood and plastic to steel and concrete, but the Department of Transportation (DOT) agencies tasked with replacing aging fenders are bypassing these options for eco-friendly, corrosion-resistant fibre reinforced polymer (FRP) pilings.

Larger vessels are driving the need for pilings that can protect ships, docks, canal entrances and the bases of bridges from damage. FiberPILE, designed and produced by Composite Advantage, is made with a proprietary closed moulding vacuum infusion method to produce high strength from its high fibre-to-resin ratio.

“FRP composites are orthotropic materials,” says CA President Scott Reeve. “That means we can tailor properties along each axis and in each direction. Fibre orientation is important because placing the majority of fibre in the axial direction optimises bending properties while fibres in the +/-45 degree direction enhance torsional resistance and pin bearing. This makes our piles stronger and lighter than other products on the market.”

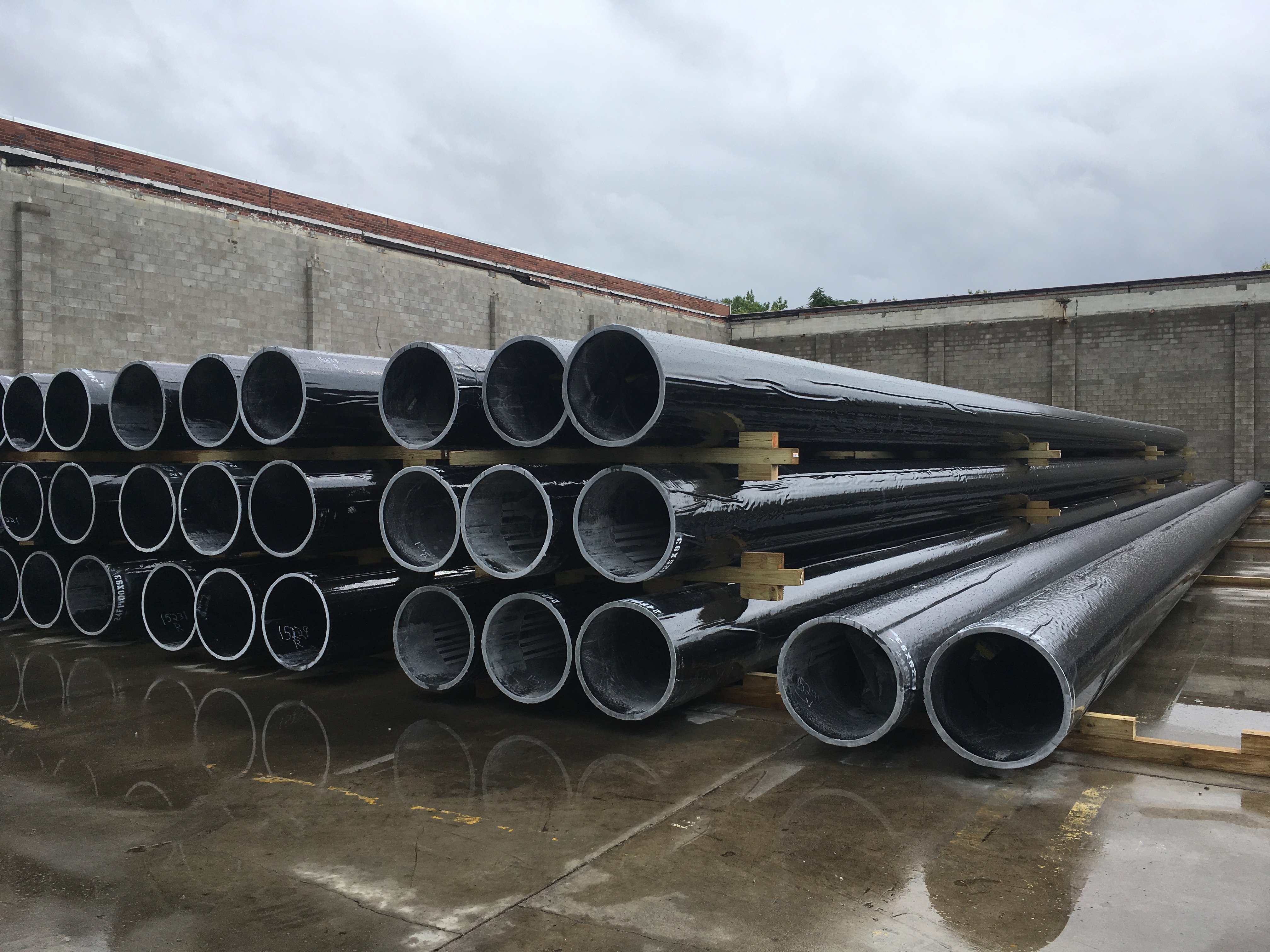

FiberPILE has the flexibility to bend under vessel contact and then return to its original shape without breakage or damage. Standard diameters range from 18 in. to 48 in. FiberPILE can be fabricated in continuous lengths up to 110 ft. The FRP product has a design modulus of 5.7 msi and a strength rating of 55 ksi.

“The unique combinations we’re able to engineer with FRP properties make it possible for us to achieve superior energy absorption,” says Reeve. “That’s why FiberPILE products can effectively absorb impact kinetic energy generated by head-on collisions from larger ships. In most cases, we can also reduce the number of FRP pilings a customer needs by as much as 50 percent when compared to steel or wood. That’s a substantial savings in terms of lower installation and total project costs.”

Hollow construction, light weight and low driving friction allow contractors to use standard equipment for installation. Additional design options include pile splices for longer piles or tight under-bridge driving; FRP wales for tight radius fenders; and traditional plastic timber wales. These horizontal wales can be coated with a brown plastic exterior to look like cedar.

Composite Advantage supplies innovative fibre reinforced polymer (FRP) products for major infrastructure markets. To create its engineered solutions, CA pairs progressive designs with its capability to mould large parts, perform on-site assembly, and support customer installations. The supplier has been developing lightweight, high-strength, cost-effective FRP goods for structurally demanding applications and corrosive environments since 2005. Many of these products have paved the way for first-time use of FRP composites in infrastructure, rail and water applications because of their performance attributes. The supplier’s comprehensive lineup includes bridge decks, trail bridges, cantilever sidewalks and rail platforms to fender protection systems, pilings, naval ship separators and other waterfront structures. CA is a member of the Creative Composites Group, a subsidiary of Hill and Smith Holdings.

Visit www.compositeadvantage.com or contact Composite Advantage at 937-723-9031 or info@compositeadvantage.com.