People across the United States are reaching for their running shoes, hiking sandals and sneakers, making sure their bike tires are full of air and stocking up on sunscreen, insect repellent and clothes made with wicking materials. On April 18, 2020, the Rails-to-Trails Conservancy—the country’s largest trails organization— will kick off opening day for America’s trails. Since the mid-1980s, RTC’s vision has been to build a rail-trail that spans the U.S. The project is more than 50 percent complete.

People across the United States are reaching for their running shoes, hiking sandals and sneakers, making sure their bike tires are full of air and stocking up on sunscreen, insect repellent and clothes made with wicking materials. On April 18, 2020, the Rails-to-Trails Conservancy—the country’s largest trails organization— will kick off opening day for America’s trails. Since the mid-1980s, RTC’s vision has been to build a rail-trail that spans the U.S. The project is more than 50 percent complete.

To date, there are 24,250 miles of rail-trails, 8,865 miles of potential rail-trail, 2,169 total rail-trails and 825 current projects. One of those active jobs is the Cheney Rail-Trail in Manchester, Connecticut. In 2016, the state’s Department of Energy and Environmental Protection awarded grants totaling $7 million for 38 projects to build, expand or enhance greenways and multi-use trails in more than 27 communities.

To date, there are 24,250 miles of rail-trails, 8,865 miles of potential rail-trail, 2,169 total rail-trails and 825 current projects. One of those active jobs is the Cheney Rail-Trail in Manchester, Connecticut. In 2016, the state’s Department of Energy and Environmental Protection awarded grants totaling $7 million for 38 projects to build, expand or enhance greenways and multi-use trails in more than 27 communities.

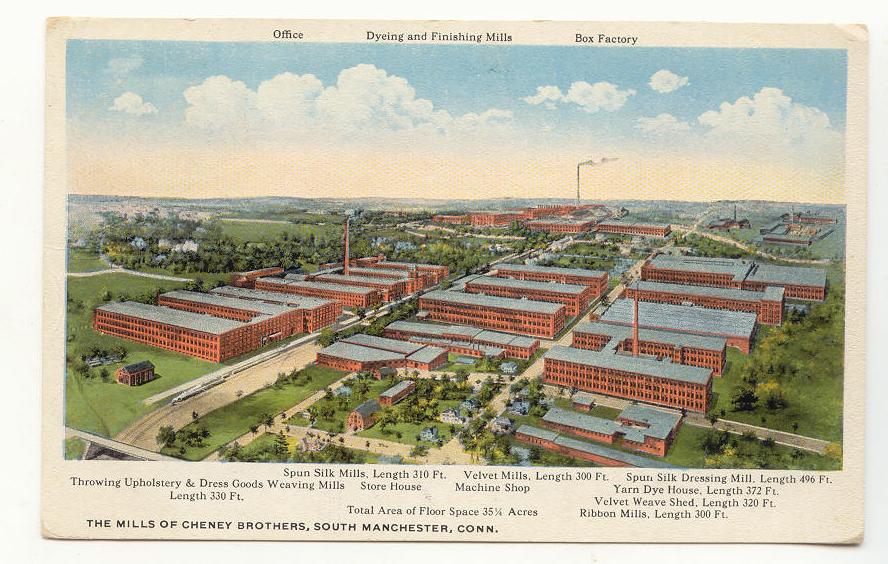

The Cheney Rail Trail follows part of the corridor of the South Manchester Railroad. The history of this area goes back to 1833 and brothers, Ward, Frank and Rush Cheney. Initially the family thought to cultivate a silk market in the U.S. by establishing mulberry trees; an essential ingredient for silk production. Morus Multicaulis wasn’t hardy and the farms soon disappeared. The Cheneys took decisive action before the silk crash and invested capital in processing silk. The business flourished and in 1869 the company built the South Manchester Railroad. Nicknamed Cheney’s Goat, the 2.5-mile rail transported silk between Manchester and Hartford mills and had the distinction of simultaneously becoming the shortest freight-and-passenger railroad in the U.S. and the longest private railroad. The area and the now extinct rail line are being refurbished as part of the new Cheney Rail-Trail.

Fiber reinforced polymer (FRP) composites are getting in on the act. If one takes a southerly stroll, the way leads behind the cement walls of businesses and dead ends at the trestle at Center Street. This site is currently being transformed with a new FRP bridge deck that will serve as a key connection for pedestrians and bicyclists that want to travel along the renovated rail-trail. An engineer for AI Engineers found Composite Advantage’s FiberSPAN product through an internet search.

Specifications called for a walkway installation on an existing steel truss bridge. With a live load requirement of 90 psf, mid-span deflection was limited to L/500 with a maximum loading of an AASHTO H-5 vehicle with a 4,000 lb. wheel load. The design also called for a wind uplift loading of 30 psf, class II fire resistance performance per ASTM E-84 and a temperature range of -40 degrees Fahrenheit to 160 degrees Fahrenheit for deck operation.

The deck comprised three FRP panels 23 ft. long by 9.5 ft. wide for a total deck length of 69 ft. The deck was prefabricated for quick installation with a crown for water drainage and curbs for guiding bicycles. The FiberSPAN deck was given a non-slip pedestrian-grade Matacryl surface.

Adoption of FRP reduced installation time and costs as well as minimizing the need for maintenance. With its’ long life cycle, lightweight, corrosion resistance and high-strength performance, I think the Cheney family would approve of the changes to their rail. The FiberSPAN deck was installed in December 2019.