Lead times, material availability and process inefficiencies are major contributors to high prices, long waits and unhappy customers. Vertical integration solves many of these problems by consolidating materials and operations. Here are five things vertical integration does to empower Creative Composites Group (CCG) to provide unparalleled value to our customers.

1. Streamlined Processes & Efficiency

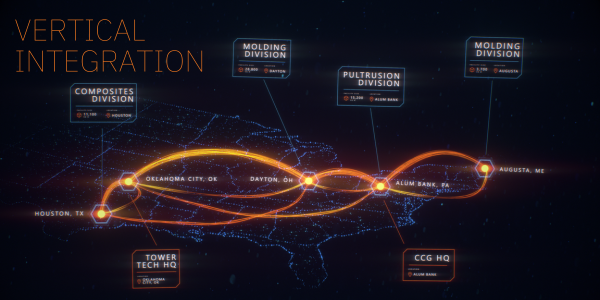

Who could forget the supply chain nightmares of 2021. Between covid-related labor shortages to a giant barge getting stuck in the Suez Canal for almost week, lead times sky-rocketed and prices rose as the supply couldn’t meet demand. CCG has never had this problem: Greater than 90% of all materials used in our process are sourced from the United States, and all our FRP products are produced in one of four U.S. facilities.

By bringing all stages of production under one roof, CCG minimizes or eliminates bottlenecks, reduces lead times, and ensures consistent quality throughout the entire process. Controlling everything in-house means that we have fine-tuned everything for maximum efficiency, from design to fabrication and distribution.

2. Quality Assurance at Every Stage

When companies have a broad supply chain and multiple vendors, there are lots of opportunities for inconsistencies to sneak into the process. If a batch of one supplier’s materials was somewhat compromised, the final product may suffer or will at least differ from other lots of the nominally same product.

Vertical integration helps us maintain our commitment to being the highest-quality FRP manufacturer. From raw material selection to our manufacturing techniques, strict oversight and control means customers can trust that FRP from CCG will always meet and usually will exceed their expectations and all industry standards.

3. Cost-Efficiency without Compromise

Vertical integration allows CCG to invest in product excellence and innovation rather than in shipping and other vendor-related costs. The cost of CCG’s product is directly correlated to its top-tier quality and not to “the cost of doing business.”

4. Customization & Adaptability

Vertical integration not only allows for efficient production but also enables rapid customization. CCG’s experts partner with customers to understand their specific needs and to come up with an innovative solution – even if it’s never been tried before, like tunnel shrouds in New York City or a single-piece cooling tower panel wall. And because materials and processes are all controlled by CCG, prototypes can swiftly be produced, and customizations can be completed in a snap.

5. Excellence in Process & People

Vertical integration also means CCG’s experts are in-house and usually on the other end of customer phone calls. Innovation and customer partnerships are led by industry professionals at the top of their field. It also allows CCG to invest heavily in research and development, especially of codes and standards, and in industry training, as with a recent training partnership with the American Composites Manufacturers Association (ACMA) to train members of the Army Corps of Engineers®. All this helps CCG lead the industry for boundary-pushing applications of FRP.

Vertical Integration Means Better FRP

CCG’s commitment to vertical integration is one way we provide unmatched value to our customers. Explore our case studies to see what we’ve helped others accomplish and contact us to discuss how we can elevate your next project.