Cantilever bridges take their name from the horizontal structural members that support the bridge’s weight on a single end. The supported end is tethered to a pier or piling so that the unsupported end can bear the weight of the bridge while withstanding shear stress, tension in the upper supports, and compression in the lower supports.

Cantilever bridges take their name from the horizontal structural members that support the bridge’s weight on a single end. The supported end is tethered to a pier or piling so that the unsupported end can bear the weight of the bridge while withstanding shear stress, tension in the upper supports, and compression in the lower supports.

Because only a single end needs to be supported, cantilevers can cover much greater distances than beams, trusses, and other common structures used in bridges. Engineers frequently combine them with river piers to span long or wide waterways that otherwise cannot be crossed due to safety considerations. The Forth Bridge in Scotland is a famous example.

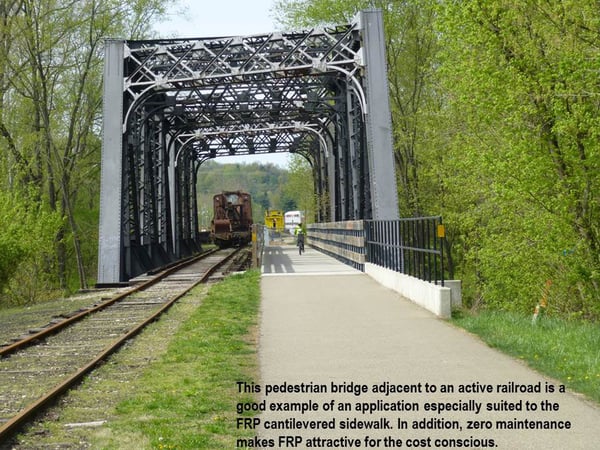

While these cantilevers are used to support the vehicle deck, the cantilever method can be used to support other elements of a bridge. In particular, they can be used to construct pedestrian walkways that extend off the side of the bridge. Since many bridges currently lack sidewalks, cantilever pathways could significantly reduce the risk of injury that many pedestrians currently face when attempting to share bridges with oncoming traffic, making transportation safer for everybody.

Using Fiber-Reinforced Polymers in Pedestrian Sidewalks

While bridges can be made safer for pedestrians by adding sidewalks to them, traditional concrete materials create a weight problem. Since many existing bridges either aren’t designed to handle additional loads or are already overburdened, transportation departments are reluctant to invest in the bridge upgrades needed to add heavy concrete sidewalks for foot traffic.

Fortunately, a viable alternative is available. FiberSPAN-C is a fiber-reinforced polymer (FRP) composite sidewalk system that’s based on the same principles that underlie cantilever bridges. As a high-strength material that’s 80% to 90% lighter than reinforced concrete panels, FiberSPAN-C can be suspended off existing bridges without sacrificing structural integrity.

Because the FRP panels used in the system are prefabricated, a FiberSPAN-C sidewalk offers shorter construction timelines and lower installation costs than other options. Moreover, it can be engineered to meet existing walkway replacement protocols. It can be placed on both sides of a bridge or on only one side as long as pedestrian crossings are included on each end of the bridge.

Why FRP Works for Sidewalks

Pedestrian sidewalks made of concrete can’t be added on most existing bridges, since the extra weight can compromise its structure. This is not an issue with lightweight FRP - their dead load of 4 to 9 psf means that a wide sidewalk with accompanying pedestrian live loads can be handled by the bridge. There a multiple safety benefits: lightweight installation; non-slip surface; and pedestrians and bicyclists don’t face vehicle traffic.

Despite its low weight, FRP is a high-strength material that can easily handle the weight of crossing pedestrians. Just as importantly, its strong resistance to water and chemical corrosion ensures that the sidewalk can last for as long as a century before it needs to be replaced.

Bridges are essential components of a region’s infrastructure, but many crossings need to be modified to suit the needs of today’s travelers. A FiberSPAN-C cantilever sidewalk enables you to make needed improvements to your community’s bridges without placing them out of commission. If you'd like to explore the benefits of FRP bridges and sidewalks in greater detail, download our eBook, Cantilever Sidewalks & FRP: The Path to Pedestrian Safety on Bridges