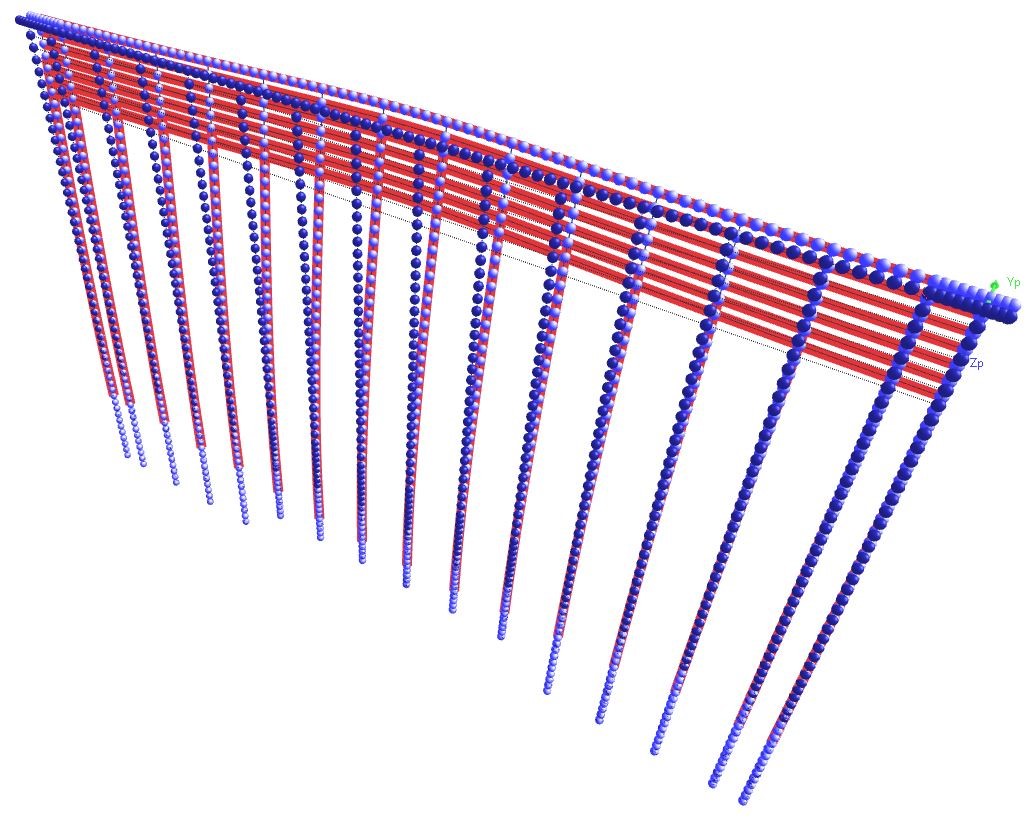

We had a great webinar last week on the design of FRP pilings. It was nice to get into the design details since FRP fender pilings provide an optimal combination of high strength and low stiffness that results in superior energy absorption.

During the webinar, we received many questions that we answered at the end of the webinar and in a follow-up to attendees. In this blog we are including some of our most frequently asked questions.

Any issues with cracking of the FRP during driving? This is typically not an issue with FRP pile so long as there are fibers in all four primary directions 0/45/-45/90. This prevents splitting. The typical issue with driving is that the grips vibrate and wear the FRP.

Can the hollow FRP pipe pile be socketed into rock? Yes. This happens all the time.

Can FRP pipe piles be filled with concrete on site? In crushing applications, the top of the pipe be filled with concrete to increase the crushing resistance.

Have you installed a fender system for a wharf structure and how did you take advantage of the deflection capabilities of the FRP since its attached to a wharf structure? For these applications, typically the top of the pile is filled with concrete to increase the crushing resistance. These applications are not energy absorbing since nothing is allowed to move.

What is the unit cost for Furnishing and Installation of FRP Pile (per linear foot)? This depends on a lot of specifics. Piles can range from $60/lf to $1,000/lf depending on the diameter and wall thickness. Driving costs vary widely depending on the soil and work restrictions. One of the values of FRP pilings is that fewer piles are needed for a fender which greatly reduces installation costs.

Any cracking due to long term service and environmental exposure? Long term FRP piles have excellent environmental resistance. Cracking is not an issue that FRP experiences.

Did you consider the issues with sulfate water? We use a vinyl ester resin that has extremely good resistance to environmental exposure.

What safety factor do you recommend to apply to the ultimate moment capacity Per FDOT Structures Manual, the typical phi factor applied for FRP piles is 0.8 (1.25 SF).

Check out our FRP library where we have many past presentations and ebooks.