FireStrong™ Self-Monitoring Composite Pole Systems

Fiber-Reinforced Polymer (FRP) is often used as an advanced material for utility poles. While the composites offer some degree of inherent fire-retardant properties that protect the structure from fire damage, composite fire-resistant poles can be added to protect your grid from the excessive heat generated by typical brush or grass fires. FireStrong utility poles maintain their structural integrity after a fire, so they can be kept in service. In addition, the integration of an irreversible temperature monitoring system helps utility workers determine whether pole strength retention was successful.

Benefits of Fire-Resistant FRP Utility Poles

FRP utility poles are engineered to last up 75 years in some of the harshest environments with little to no maintenance. Adding fire-resistant poles further increases their durability and longevity in fire-prone areas. As a result, fire rated poles will be less susceptible to damage and degradation caused by the heat from a fire.

FireStrong Power Pole Benefits:

- Grid Resiliency - Peace-of-Mind no Matter the Conditions

- Self Extinguishing - V0 Rating (UL94)

- Third-Party Fire Testing - Added Safety & Grid Resiliency

- Product Engineering - To Combat Fire

- Long-Term Reliability - Patented Technology for Post-Fire Inspections

- Low Conductivity- High Dielectric Strength

- Corrosion Resistance - Withstands Coastal & Harsh Environments

- Protects People & Environment - No Dangerous Pesticides or Treatment Chemicals

- Sustainable Manufacturing - Made in the USA

The key benefits of non-combustible FireStrong poles are ignition prevention, increased grid resiliency and cost savings. For example, if and when a fire occurs, a grid protected by FireStrong power poles will be less likely to experience a failure. As a result, they will not need to be removed and replaced, meaning utility companies will not need to invest time and money into performing these operations, and end customers will not need to suffer grid downtime.

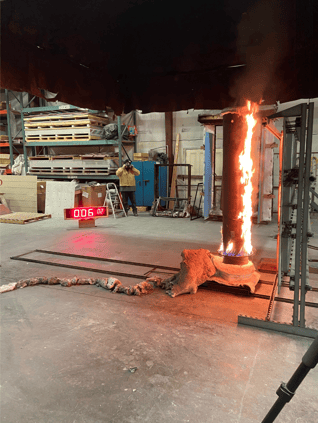

Fire Testing Resulted in 100% Retention of Design Strength

A third-party testing agency tested the poles by simulating a chaparral wildfire. FireStrong poles are also classified as self-extinguishing per UL94 with a V0 rating.

The FireStrong poles passed tests of 2 minutes at 2,100 degrees Fahrenheit. The FRP poles that did not buckle during burn tests met the GO95 and NESC strength and deflection requirements during break testing. Most U.S. manufacturers use steel rated from 50,000 to 55,000 psi. Tested FRP poles were rated at 78,000 psi. FRP poles retained 4,500 lbs. design strength [the maximum load that can be applied without causing pole failure]. FireStrong’s high dielectric strength passed ‘hot stick’ recertification tests under ASTM F7111 and IEEE 978.

Why Integrate a Temperature Monitoring System in Utility Poles?

FireStrong poles ship with an irreversible temperature monitoring system that is placed against the FRP pole. The system is engineered to continuously monitor the temperature experienced by the pole and permanently record the highest temperature measured on its surface. During post-fire inspections, utility workers can compare this measurement to a temperature vs. strength retention chart for the particular type of FRP pole to evaluate whether the utility pole has to be replaced. This step helps shorten the amount of time required for inspections without sacrificing the quality of the results.